Takara Standard

The making of enamel

High-quality enamel makes peoples lifes better!

This is the mission of Takara Standard.

In order to create products which will be "loved" by our customers, Takara Standard pay special attention to the quality. We carefully observe and touch the products during the production process to ensure each product is in its best quality. This is the attitude of the Japanese.

The production of enamel depends on the temperaure and humidity of the day and must be adjusted accordingly. It is difficult for machines to make fine adjustments to such subtle changes every day, thus only humans quality craftmanship can accomplish it.

Each production process is like a relay race, where workers pass on the product to complete each production step precisely. The products are handcrafted by many workers; this is how Takara Standard is able to maintain its extremely high quality.

We believe that it is essential to provide high-quality and reliable products, to create a brand that would be loved by our customers.

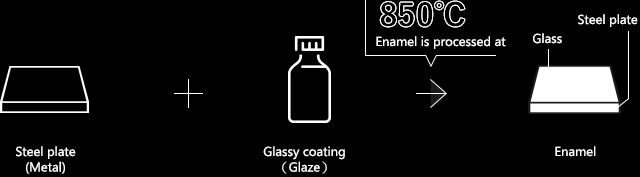

First of all, what is Enamel?

The manufacturing process of enamel

Steel plate processing

We process steel sheets according to different purposes. Workers use mechanical weldings to processe steel sheets.

「Takara Standard Tehnology」

Experienced workers handle the processing work of complex shapes. This is a difficult task for robots.

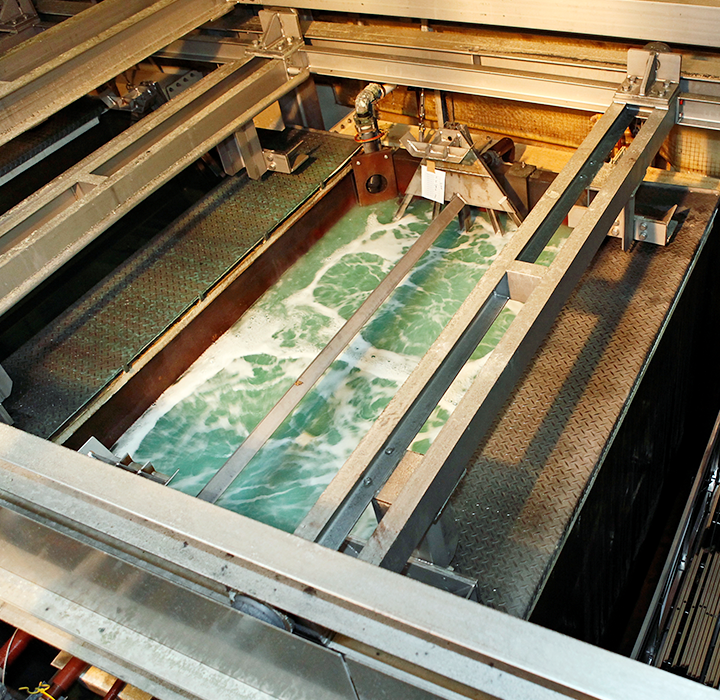

Preprocessing

In order to improve the adhesion between the steel sheet and the glassy coating, the processed steel sheet is pretreated in the flow of "defatting → pickling → nickel treatment → neutralization".

【Solvent defatting】

Remove oil from the iron plate surface.

【Pickling】

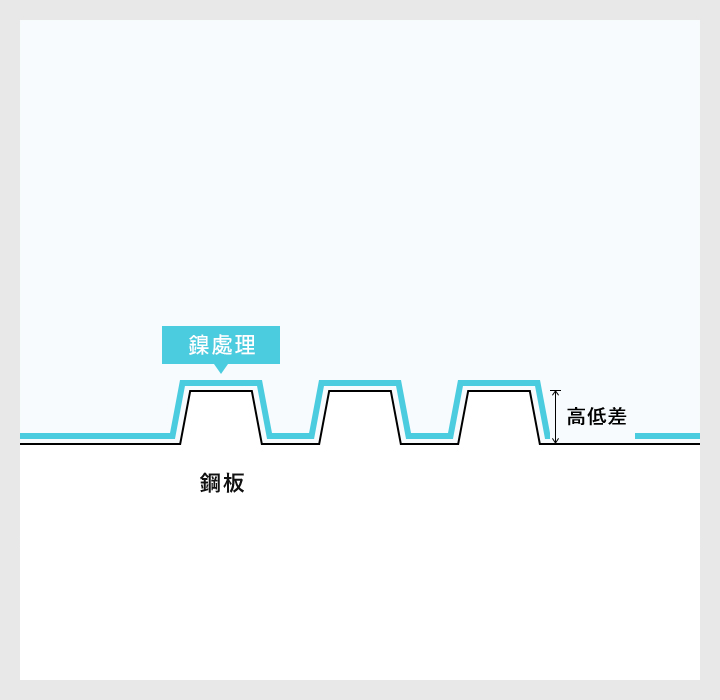

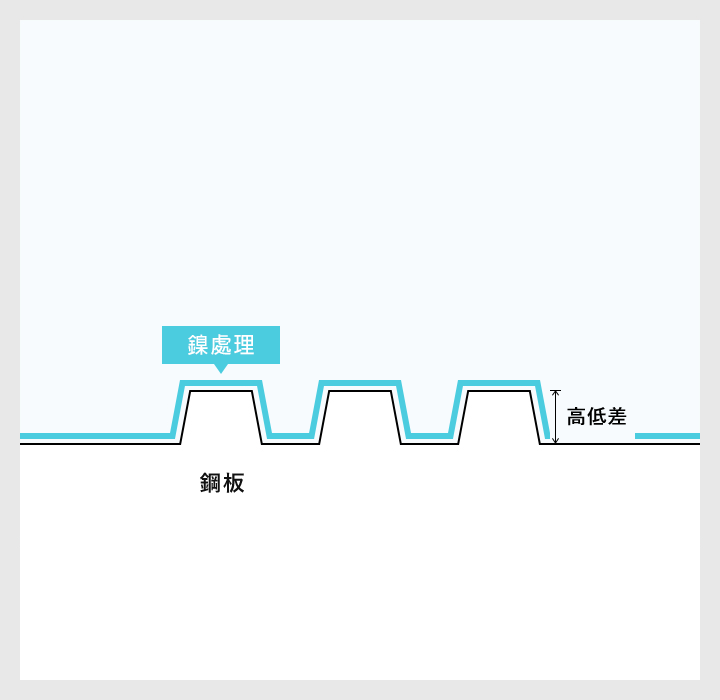

Immerse in sulfuric acid to make the surface of the steel sheet slightly uneven. This increases the contact area with the glassy coating and improves the adhesion between the steel plate and the coating.

「Takara Standard Technology」

The steel plate is jointly developed with a professional Japanese manufacturer. We have developed an optimal steel sheet that has a high degree of adhesion to the coating, which is easy to create uneven surface and less bubbles. This steel plate enhances the quality of enamel.

The greater the difference in height, the greater the area where the coating adheres, and the stronger the adhesion between the steel plate and the glass.

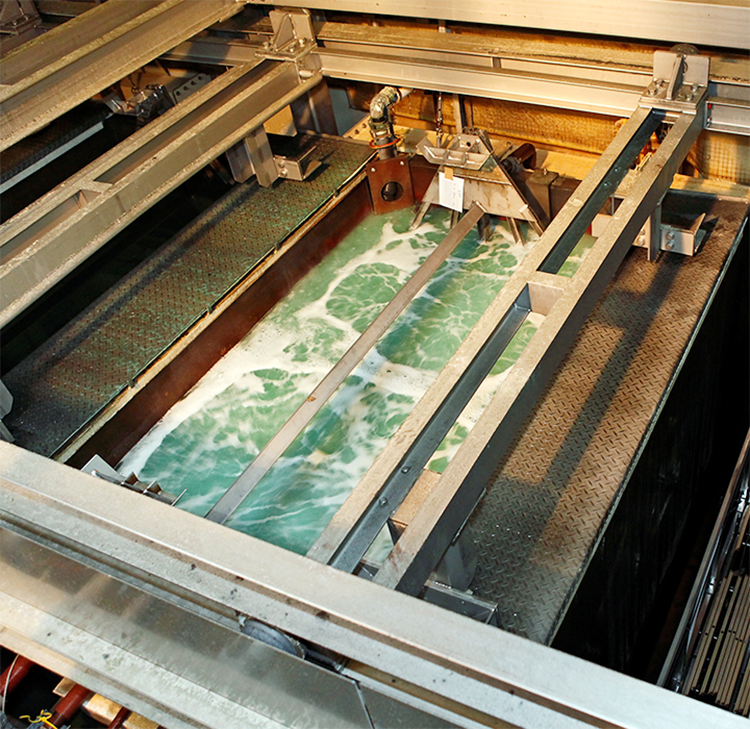

【Nickel Treatment】

While nickel is attached to the steel sheet, there is a chemical reaction which improves the adhesion between the steel sheet and the glass

【Neutralization】

Both pickling and nickel treatment are soaked in acidic liquid. Since metal could be corroded by acid, the steel sheet will be immersed in an alkaline liquid for neutralization

「Takara Standard Technology」

The concentration, time, and temperature of nickel treatment are all unique techniques of Takara Standard.

Manufacturing of glass

【Frit blending / mixing】

The glaze is made by glass powder mixed wit silica stone, feldspar, borax, soda ash, etc. All ingrediences are mixed in an appropriate ratio.

「Takara Standard Technology」

The glaze formulation is an important process that directly affects the quality of enamel. Depending on the enamel usage, Takara Standard created about 600 unique formulations with different specifications by performance, color, luster, productivity.

【Frit】

The mixture is melted at a high temperatur of 1200°C-1300°C. There are two main melting methods."Continuous smelting furnace" for mass production and "intermittent smelting furnace" for small batch production. The molten raw material will be rapidly cooled and crushed into glass, called "frit".

【Mill】

Clay, water, and various chemicals are added to the frit and crushed into a mud-like glaze.

Glazed

The glass coating will be evenly sprayed on the processed steel plate and dried thoroughly to remove the moisture. If it enters the furnace in a wet state, it may destroy the evenly applied glass coating while the moisture evaporates.

「Takara Standard Technology」

This process directly affects the quality of enamel. Workers check the steel plates thoroughly while applying the glass coating evenly.

Takara Standard will use various methods depending on the shape and size. High voltage is applied to the glaze to make it an "electrostatic coating" viscosity. Workers apply the glaze with a spray gun, or directly immerse the steel plate in the glaze.

Burning

Takara Standard burns the processed steel plate at a high temperature of about 850°C. The milled glass coating will slowly melt. The crystals in the glass will change colour in the heat and become an enamel with a smooth glass surface.

「Takara Standard Technology」

In order to produce different colors, it is very important to precisely control the burning temperature.

Assembly ・inspection

packing ・ shipping

Each piece of enamel undergoes strict inspections, such as checking the thickness of the coating and the color difference. Since Takara Standard enamel will be used for various parts, it will be assembled and cut according to the product. The enamel will be packaged and shipped after inspection.

「Takara Standard Technology」

The product will be assembled with the help of many people. Workers will touch them with their hands and carefully inspect them to ensure the products are in perfect condition.

The manufacturing process of enamel

Steel plate processing

We process steel sheets according to different purposes. Workers use mechanical weldings to processe steel sheets.

「Takara Standard Tehnology」

Experienced workers would handle the processing work of complex shapes. This is a difficult task for robots.

Preprocessing

In order to improve the adhesion between the steel sheet and the glassy coating, the processed steel sheet is pretreated in the flow of "defatting → pickling → nickel treatment → neutralization".

【Solvent defatting】

Remove oil from the iron plate surface.

【Pickling】

Immerse in sulfuric acid to make the surface of the steel sheet slightly uneven. This would increase the contact area with the glassy coating

and improve the adhesion between the steel plate and the coating.

Takara Standard Technology

The steel plate is jointly developed with a professional Japanese manufacturer. We have developed an optimal steel sheet that has a high degree of adhesion to the coating, which is easy to create uneven surface and less bubbles. This steel plate enhances the quality of enamel.

The greater the difference in height, the greater the area where the coating adheres, and the stronger the adhesion between the steel plate and the glass.

【Nickel Treatment】

While nickel is attached to the steel sheet, there is a chemical reaction which improves the adhesion between the steel sheet and the glass

【Neutralization】

Both pickling and nickel treatment are soaked in acidic liquid. Since metal could be corroded by acid, the steel sheet will be immersed in an alkaline liquid for neutralization

「Takara Standard Technology」

The concentration, time, and temperature of nickel treatment are all unique techniques of Takara Standard.

Manufacturing of glass

【Frit blending / mixing】

The glaze is made by glass powder mixed wit silica stone, feldspar, borax, soda ash, etc. All ingrediences are mixed in an appropriate ratio.

「Takara Standard Technology」

The glaze formulation is an important process that would directly affects the quality of enamel. Dependsing on the enamel usage, Takara Standard created about 600 unique formulations with different specifications by performance, color, luster, productivity.

【Frit】

The mixture is melted at a high temperatur of 1200°C-1300°C. There are two main melting methods."Continuous smelting furnace" for mass production and "intermittent smelting furnace" for small batch production. The molten raw material will be rapidly cooled and crushed into glass, called "frit".

【Mill】

Clay, water, and various chemicals are added to the frit.and crushed into a mud-like glaze.

Glazed

The glass coating will be evenly sprayed on the processed steel plate and dried thoroughly to remove the moisture. If it enters the furnace in a wet state, it may destroy the evenly applied glass coating while the moisture evaporates.

「Takara Standard Technology」

This process directly affects the quality of enamel. Workers check the steel plates thoroughly while applying the glass coating evenly.

Takara Standard will use various methods depending on the shape and size. High voltage is applied to the glaze to make it an "electrostatic coating" viscosity. Workers would apply the glaze with a spray gun, or directly immerse the steel plate in the glaze.

Burning

Takara Standard burns the processed steel plate at a high temperature of about 850°C. The milled glass coating will slowly melt. The crystals in the glass will change colour in the heat and become an enamel with a smooth glass surface.

「Takara Standard Technology」

In order to produce different colors, it is very important to precisely control the burning temperature.

Assembly ・inspection

packing ・ shipping

Each piece of enamel undergoes strict inspections, such as checking the thickness of the coating and the color difference. Since Takara Standard enamel will be used for various parts, it will be assembled and cut according to the product. The enamel will be packaged and shipped after inspection.

「Takara Standard Technology」

The product will be assembled with the help of many people. Workers will touch them with their hands and carefully inspect them to ensure the products are in perfect condition.

Takara Standard's high-quality enamel is used as interior and exterior materials for system kitchens, Emawall, kitchen panels, washstand etc. Enamel is easy to clean and very durable, you can use it for a long time.

We believe that enamel has a kind of attraction which makes the products to be "loved".